Proton Conducting Membranes for Energy Applications

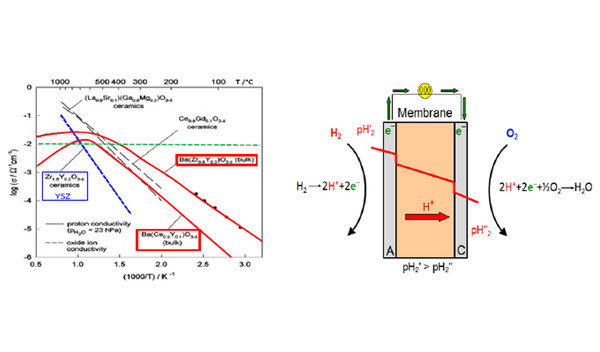

Hydrogen-based electricity generation is an important component in ‘Energiewende’, and ceramic materials can play a key role in improving the efficiency of the process. For example, ceramic permeation membranes are key to the improved performance and efficiency of proton ceramic fuel cells (PCFC) and high- temperature water-gas shift reactors for hydrogen production.

Although these devices have different functions, the proton-conducting electrolyte membrane in a PCFC and the hydrogen permeation membrane in a water-gas shift reactor have certain common requirements: they must both be gas-tight and have selective transport properties. In both systems, the functions of the membranes are influenced not only by their intrinsic materials properties but also by their microstructures. And for successful scale-up of the devices, in both cases large-area membranes are required.

In this project, Ba(Zr,Ce,Y)O3-δ perovskite materials are investigated for PCFC. The primary aim is to lower the grain boundary resistance of the ceramic while maintaining an appropriate sintering temperature for large area fabrication. For water-gas shift reactors, the recently developed La28-xW4+xO54+δ ceramic with a fluorite-related structure is studied with the goal of understanding its bulk defect chemistry and grain boundary contributions to its conductivity.

To optimize the transport properties of these materials at device scale, a combination of fundamental scientific investigation and application-oriented testing is required. Detailed microstructural and chemical characterization, focusing on defects and grain boundaries, is being performed by the StEM group, in collaboration with the Ernst Ruska-Centre in Aachen, Germany. In-situ heating and biasing facilities are under development here in Stuttgart to study the membranes during operation, which will allow us to test methods for improving their transport properties.

These TEM investigations are proceeding in parallel with, and are complemented by, the work of the other project partners. Researchers at the Institute of Energy and Climate Research at Forschungszentrum Jülich GmbH are experts in ceramic material and process development and membrane fabrication. Expertise in bulk defect chemistry and oxide properties is provided by members of Dept. Maier here at MPI-FKF.

We would like to acknowledge the Bundesministerium für Bildung und Forschung (BMBF) for funding this project.