Custom-made nanotubes

Carbon nanotubes can be specifically produced with a desired structure from suitable precursor molecules

In future, it will be possible to specifically equip carbon nanotubes with properties which they need for electronic applications, for example. Researchers at Empa in Dübendorf/Switzerland and the Max Planck Institute for Solid State Research in Stuttgart have succeeded for the first time in growing single-walled carbon nanotubes (CNTs) with only a single, prespecified structure. The nanotubes thereby have identical electronic properties. The decisive trick here: The team has taken up an idea which originated from the Stuttgart-based Max Planck researchers and produced the CNT from custom-made organic precursor molecules. The researchers started with these precursor molecules and have built up the nanotubes on a platinum surface, as they report in the latest issue of the scientific journal Nature. Such CNTs could be used in future, for instance, in ultra-sensitive light detectors and very tiny transistors.

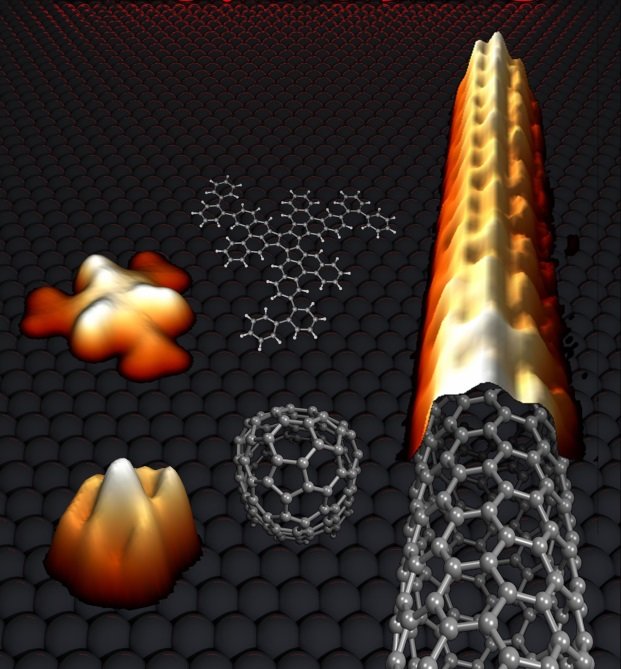

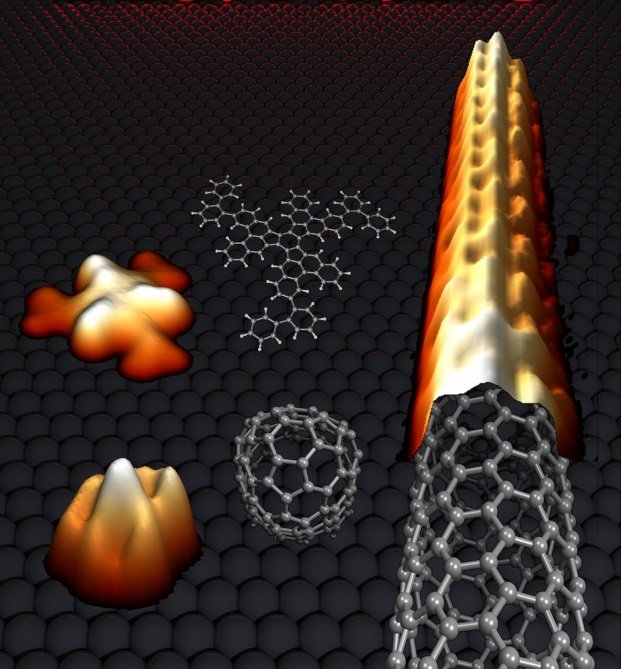

Even a nanotube has small beginnings: An end cap is produced from planar carbon, which forms the seed for the growth of a carbon nanotube. In the figure on the left, the computer images calculated were supplemented with images taken with a scanning tunnelling microscope.

For 20 years, material scientists working on the development of carbon nanotubes for a range of applications have been battling a problem – now an elegant solution is at hand. With their unusual mechanical, thermal and electronic properties, the tiny tubes with their honeycomb lattice of graphitic carbon have become the embodiment of nanomaterials. They could be used to manufacture the next generation of electronic and electro-optical components so that they are even smaller and with even faster switching times than before. But to achieve this, the material scientists must specifically equip the nanotubes with desired properties, and these depend on their structure. The production methods used to date, however, always result in a mixture of different CNTs. The team from Empa and the Max Planck Institute for Solid State Research has now remedied the situation with a new production path for single-walled nanotubes.

Carbon nanotubes with the best possible varietal purity are in demand

With a diameter of around one nanometre, single-walled CNTs (SWCNTs) are deemed to be quantum structures; very tiny structural differences, in the diameter, for example, or in the orientation of the atomic lattice, can dramatically change the electronic properties: one SWCNT can be a metal, while one with a slightly different structure is semi-conducting. Correspondingly great is the interest in reliable methods for producing SWCNTs with the best possible varietal purity. Researchers working with Martin Jansen, Director Emeritus at the Max Planck Institute for Solid State Research, have been pursuing suitable concepts for the synthesis for ten years. But it is only now that the surface physicists at Empa and the chemists at the Stuttgart-based Max Planck Institute have succeeded in implementing one of these ideas in the laboratory. The researchers allowed structurally identical SWCNTs to grow on a platinum surface in a self-organised process and were able to unambiguously define their electronic properties.

The Max Planck research team headed by Martin Jansen had the idea of starting with small precursor molecules to synthesise carbon nanotubes. They felt it should be possible to achieve controlled conversion of the precursor molecules into a cap which acts as the seed for a SWCNT and thus unambiguously specify the structure of the nanotube. With this concept, they approached the Empa team working with Roman Fasel, head of Empa’s «nanotech@surfaces» department and titular professor at the Department of Chemistry and Biochemistry of the University of Bern. This group has already been working for some time on how molecules on a surface can be converted or combined into complex nanostructures according to the principle of molecular self-organisation. “The challenge now consists in finding the right precursor molecule which would actually grow on a smooth surface,” says Roman Fasel. This was ultimately achieved by Andreas Mueller and Konstantin Amsharov from the Max Planck Institute in Stuttgart with the synthesis of a hydrocarbon molecule from a not-inconsiderable 150 atoms.

Molecular origami on the platinum surface

What exactly is the process in which the carbon nanotube forms? In the first step, the flat precursor molecule must – as is the case in origami – convert into a three-dimensional object, the seed. This takes place on a hot platinum surface with the aid of a catalytic reaction, whereby hydrogen atoms split off from the precursor molecule and form new carbon-carbon bonds at very specific positions. The seed folds up from the flat molecule: a tiny, domed shape with open rim, which sits on the platinum surface. This so-called end cap forms the top of the growing SWCNT.

In a second chemical process, further carbon atoms, which are formed during the catalytic decomposition of ethanol on the platinum surface, are taken up. They deposit on the open rim between end cap and platinum surface and lift the cap higher and higher; the tube slowly grows upwards. The atomic structure of the nanotube is determined solely by the shape of the seed. The researchers proved this by analysing the vibrational modes of the SWCNTs and taking measurements with the scanning tunnelling microscope. Further investigations at Empa showed that the SWCNTs produced were over 300 nanometres in length.

Different nanotubes are formed from suitable precursor molecules

The researchers have thus proved that they can unambiguously specify the growth and thus the structure of long SWCNTs using custom-made molecular seeds. The SWCNTs synthesised in this study can exist in two forms, which correspond to an object and its mirror image. By choosing the precursor molecule appropriately, the researchers were able to influence which of the two variants forms. Depending on how the honeycomb atomic lattice is derived from the original molecule – straight or oblique with respect to the CNT axis – it is also possible for helically wound tubes, i.e. with right- or left-handed rotation, and with non-mirror symmetry to form. And it is precisely this structure that then determines which electronic, thermo-electric and optical properties of the material. In principle, the researchers can therefore specifically produce materials with different properties through their choice of precursor molecule.

In further steps, Roman Fasel and his colleagues want to gain an even better understanding of how SWCNTs establish themselves on a surface. Even if well in excess of 100 million nanotubes per square centimetre already grow on the platinum surface, only a relatively small fraction of the seeds actually develop into «mature» nanotubes. The question remains as to which processes are responsible for this, and how the yield can be increased.

Empa/PH